Skoltech researchers have made a groundbreaking discovery in the field of hydrogen production. They have devised a method to extract hydrogen from natural gas with an impressive 45% efficiency directly within gas fields. By introducing steam and a catalyst into a well and igniting the gas with oxygen, they are able to generate a mixture of carbon monoxide and hydrogen, which can then be easily separated to obtain pure hydrogen. This innovative technology has the potential to accelerate the shift from fossil fuels to clean hydrogen energy.

The current reliance on fossil fuels, such as oil and natural gas, poses a significant threat to the environment due to the emission of carbon dioxide during combustion. While natural gas is considered a cleaner alternative to oil, it still contributes to greenhouse gas emissions. In contrast, hydrogen offers a sustainable solution as it only produces water vapor when utilized as an energy source. However, challenges related to hydrogen production have hindered its widespread adoption.

The research team from the Skolkovo Institute of Science and Technology has introduced a novel approach to extract hydrogen from the hydrocarbons present in natural gas reservoirs. By leveraging the molecular hydrogen content found in hydrocarbons, they have devised a method to obtain a substantial amount of green fuel from these reservoirs.

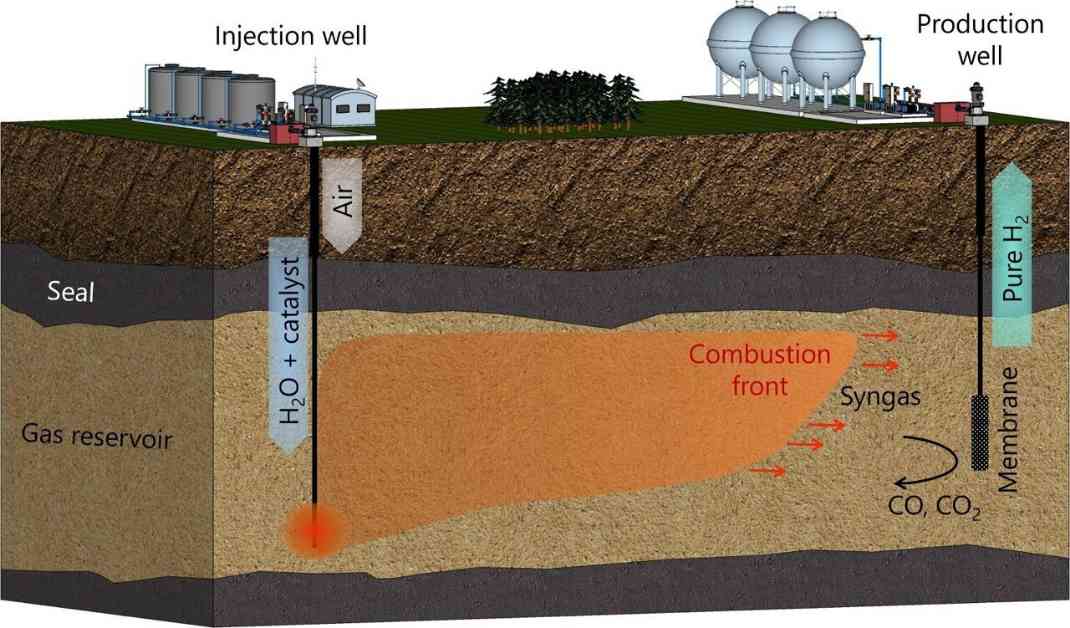

The process involves injecting steam and a catalyst into the well to facilitate the separation of hydrogen from the natural gas components. Subsequently, the gas is ignited directly in the reservoir using air or pure oxygen. Through this method, the natural gas undergoes combustion, resulting in the production of carbon monoxide and hydrogen. Importantly, the carbon dioxide generated from the combustion process remains sequestered underground, minimizing its environmental impact.

In laboratory experiments conducted to simulate real gas reservoir conditions, the researchers achieved a hydrogen yield of 45% by maintaining a high temperature of 800°C and injecting ample steam into the reactor. The efficiency of the hydrogen production process was further influenced by the composition of the rock used in the experiments. For instance, porous alumina demonstrated a higher hydrogen yield of 55% due to its inert nature.

Elena Mukhina, a senior research scientist at Skoltech Petroleum and the project leader, expressed optimism about the potential of their approach to convert hydrocarbons into green fuels with up to 45% efficiency in field environments. The team plans to further validate their method in real gas fields to assess its scalability and practicality.

This innovative research opens new possibilities for sustainable hydrogen production and marks a significant step towards reducing reliance on fossil fuels. The findings have been published in the journal Fuel, showcasing the scientific advancements in the field of energy production. As the world seeks cleaner energy solutions, the conversion of natural gas into hydrogen directly in gas fields presents a promising pathway towards a greener future.